해외 검사원 자격시험 자료 공유합니다

먼저 영어 공부를 선행하시고 시험 준비하기를 권장드립니다 본인은 일전에 드릴쉽승선해서 검사한 경험있는데 영어가들리지 않아 곤란한경험이 여러번있었습니다

일단 해외자격시험은 국내 자격보다 어렵지 않습니다 다만 영어로 시험이 진행된다는 점이 어려울뿐입니다

API 시험을 치고나서 느낌은?

시험코드는 반듯이 정독해보시고 시험 치세요 대분분의 문제가 해당코드에서 출제 됩니다 그리고 공부방법은 기출문제를 풀어보고 그문제가 어디에서 나오는지 알아야 한다는 것입니다 그것은 추가코드를 공부할때도 마찬가지 입니다 문제를 풀때 앞의 목차를 보면서 어디에서 나올것 같은지 한번씩 생각해 보시기를 추천 드립니다

아직 공유안한 자료들 많이 있습니다 혹시 필요하신분들 댓글 달아주세요 (510,570, 653, ASNT L3, CWI 등...기타 각종 코드 필요하신분들 )

국내 최저가 화상영어 추천(한달 6만원 20회 20분)

국내 최저가 화상영어 (한달 6만원 20회 20분)

국내 최저가 화상영어 추천(한달 5만원 20회 20분) 아직도 말 못하는 수업만 하고 계신가요? ‘영어는 공부’가 아니라 ‘언어’라는 점을 아셔야 합니다 때문에 당연히 원어민과 대화를 하면서

qi-inform.tistory.com

1) For ultrasonic testing, which of the following statements is true?

초음파 검사에 대한 설명으로 옳은 것은?

| a. | It is easy to identify all defects (모든 결함을 식별하기 쉽습니다.) |

| b. ( answer ) | The equipment should be calibrated before use (장비는 사용하기 전에 보정해야 합니다.) |

| c. | The equipment cannot be automated (장비를 자동화할 수 없습니다.) |

| d. | Sound waves will not travel through copper (음파는 구리를 통과하지 않습니다.) |

UT Disadvantages:

- Trained and skilled operator required

- Requires high operator skill

- Good surface finish required

- Defect identification

- Couplant may contaminate

- No permanent record

- Calibration Required

- Ferritic Material (Mostly)

Why:

Calibration refers to the act of evaluating and adjusting the precision and accuracy of measurement equipment. In ultrasonic testing, several forms of calibration must occur. First, the electronics of the equipment must be calibrated to ensure that they are performing as designed. This operation is usually performed by the equipment manufacturer and will not be discussed further in this material. It is also usually necessary for the operator to perform a “user calibration” of the equipment. This user calibration is necessary because most ultrasonic equipment can be reconfigured for use in a large variety of applications. The user must “calibrate” the system, which includes the equipment settings, the transducer, and the test setup, to validate that the desired level of precision and accuracy are achieved. The term calibration standard is usually only used when an absolute value is measured and in many cases, the standards are traceable back to standards at the National Institute for Standards and Technology.

2) Which of the following standards is concerned with welder approval?

다음 중 용접사 승인과 관련된 기준은?

| a. | BS EN 499 |

| b. | BS EN 288 |

| c. | BS EN 22553 |

| d. ( answer ) | BS EN 287 |

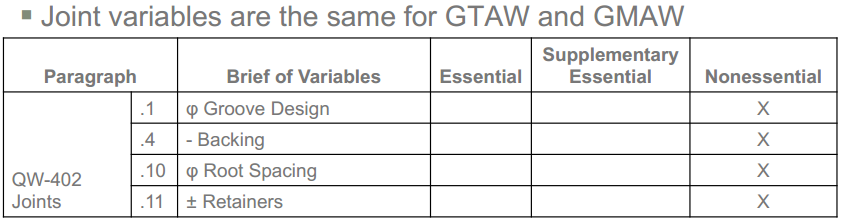

3) The WPS calls for a root gap to be between 2 and 3mm, the actual measured gap is 4mm, … of action would you like?

WPS는 2~3mm 사이의 루트 간격을 요구하며 실제 측정된 간격은 4mm입니다.

| a. | Accept it as its only 1mm (단지 1mm로 받아들여라) |

| b. ( answer ) | Reject it (거절하다) |

| c. | The welder will decide, if it fails it will be his problem (용접공이 결정할 것입니다. 실패하면 그의 문제가 될 것입니다.) |

| d. | The welder insists he can weld the butt joint easily so let him go ahead (용접공은 맞대기 이음부를 쉽게 용접할 수 있다고 주장하므로 계속 진행하도록 하십시오.) |

Pls understand that:

- With Welding inspector position: We have follow Approved WPS stricly! Any difference with WPS will be rejected. But:

- With Welding engineer: it can cosider to checked again. For ex: if it is checked follow ASME IX: root spacing is Nonessential –> can accept.

4) What is the abbreviation for a Welding Procedure Specification that has been written for the purpose of qualifying a Weld Procedure Test weld?

용접 절차 테스트 용접 을 인증하기 위해 작성된 용접 절차 사양의 약어는 무엇입니까 ?

| a. | WPS |

| b. ( answer ) | pWPS |

| c. | uWPS |

| d. | pWPT |

Pls see attached link: WPS understanding.

- pWPS: Some codes, such as AWS D1.1, allow “Prequalified WPS”, whereby it is established that the WPS written per code will produce welds with correct mechanical and metallurgical properties. It is NOT NEED to prepare a PQR in such cases. However, the pre-qualified WPS have a specified range (TABLE 3.X) of parameters under which the weld must be produced. When welding variables fall outside these ranges, a WPS with supporting PQR must be prepared.

- PQR: is a record of the weld data used to weld a test coupon. It also contains the test results of the tested specimens. The completed PQR shall document all the essential when required supplementary essential variables for each welding process used during the welding of test coupon. Non essential variables used during the welding of the coupon may be recorded.

- WPS: is a written document that provides direction to the welder or welding operator for making production welds in accordance with code requirements. The completed WPS shall describe all the essential , non essential and when required supplementary essential variables for each welding process used in the WPS.

One question: between WPS & PQR – which one have first?

- To come out a WPS we need follow these below steps – 5 steps:

- Five Step Process to Qualify a Welding Procedure

1. Understand the intended application for which the WPS will be used

2. Develop a draft procedure

3. Make a qualification weld

4. Test the qualification weld

5. Write up the WPS - Step No. 2: we can understand it is pWPS ( prequalified WPS )

- Step No. 3: it is PQR

So, between WPS & PQR: PQR have first.

5) How are the lengths of tack welds during assembly and fit up determined?

조립 및 맞춤 동안 가용접 길이는 어떻게 결정됩니까?

| a. | By the welders as they have extensive knowledge(풍부한 지식을 가진 용접공에 의해) |

| b. ( answer ) | The fabrication specification will give minimum tack length requirements(제조 사양은 최소 압정 길이 요구 사항을 제공합니다.) |

| c. | The fabrication drawing will give all the information(제작 도면은 모든 정보를 제공합니다) |

| d. | Any length of tack weld will do for assembly(모든 길이의 압정 용접은 조립에 적합합니다) |

For information:

Qualification of tack welds, a topic that is being interpreted differently by various companies. Tack welds on EXC2, EXC3 and EXC4 components are required to be welded in accordance with a qualified WPS. Tack welds are to be a maximum length of 4x the thickness of the thicker part or 50mm “…unless a shorter length can be demonstrated as satisfactory…”.

6) What does the term WPS mean?

WPS라는 용어는 무엇을 의미합니까?

| a. | Weld productivity specification (용접 생산성 사양) |

| b. | Weld production scheme (용접 생산 방식) |

| c. ( answer ) | Welding procedure specification (용접 절차 사양) |

| d. | Work productivity standard (업무 생산성 기준) |

Pls see question No. 4

7) What does the term WPQR mean?

WPQR이라는 용어는 무엇을 의미합니까?

| a. | Weld productivity quality review (용접 생산성 품질 검토) |

| b. | Weld productivity quality requirements (용접 생산성 품질 요구 사항) |

| c. ( answer ) | Welding procedure qualification record (용접 절차 자격 기록) |

| d. | Work production quantity review (작품제작 수량검토) |

Pls see question No. 4

8) Is it always necessary to preheat the base material before welding?

용접하기 전에 항상 모재를 예열해야 합니까?

| a. | Not on a sunny day (화창한 날이 아닌) |

| b. ( answer ) | Only in accordance with the WPS (WPS에 따라서만) |

| c. | If the equipment is available it must be used (장비를 사용할 수 있는 경우 사용해야 합니다.) |

| d. | If using cellulosic rods these will provide enough heat (셀룰로오스 막대를 사용하는 경우 충분한 열을 제공합니다.) |

It depens on the thickness of material / type of material.

9) Which of the following would not be required to be checked before welding?

다음 중 용접 전에 점검할 필요가 없는 것은?

| a. | The welding consumables (용접 소모품) |

| b. | The weld root gap (용접 루트 갭) |

| c. ( answer ) | PWHT temperature range (PWHT 온도 범위) |

| d. | The weld preparation (용접 준비) |

PWHT: POST WELD HEAT TREATMENT – are used to change the properties of the weld metal, controlling the formation of crystalline structures.

PWHT is a mandatory requirement when certain criteria are met, the main one being the thickness. BS EN 13445 and BSPD 5500 require that joints over 35mm thick are PWHT’d, ASME VII above 19mm. If, however, the vessel is to enter service where stress corrosion is a possibility, PWHT is mandatory, irrespective of thickness. The soak time is also dependant on thickness. As a very general rule this is one hour per 25mm of thickness; for accuracy, reference must be made to the relevant specification.

Post Weld Heat Treatment (PWHT):

So what does the term ‘post weld heat treatment’ mean? To some engineers it is a rather vague term that is used to describe any heat treatment that is carried out when welding is complete. To others however, particularly those working in accordance with the pressure vessel codes such as BS PD 5500, EN 13445 or ASME VIII, it has a very precise meaning. When an engineer talks of post weld heat treatment, annealing, tempering or stress relief it is therefore advisable.

10) How do we determines what the correct weld preparation (root gap, root face, included angle) should be?

올바른 용접 준비(루트 갭, 루트 면, 사이각)가 무엇인지 어떻게 결정합니까?

| a. ( answer ) | By consulting the WPSs (WPS에 문의하여) |

| b. | The fabrication drawing will give all the information (제작 도면은 모든 정보를 제공합니다) |

| c. | The welder will decide (용접사가 결정할 것입니다.) |

| d. | The inspectors will recommend what is suitable (검사관이 적합한 것을 추천합니다.) |

'inspection > CSWIP' 카테고리의 다른 글

| CSWIP3.1 기출 Q&A 해설 8(번역 포함) (3) | 2023.02.15 |

|---|---|

| CSWIP3.1 기출 Q&A 해설 7(번역 포함) (1) | 2023.02.15 |

| CSWIP3.1 기출 Q&A 해설 5 (0) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 4 (2) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 3 (0) | 2023.02.14 |

댓글