해외 검사원 자격시험 자료 공유합니다

먼저 영어 공부를 선행하시고 시험 준비하기를 권장드립니다 본인은 일전에 드릴쉽승선해서 검사한 경험있는데 영어가들리지 않아 곤란한경험이 여러번있었습니다

일단 해외자격시험은 국내 자격보다 어렵지 않습니다 다만 영어로 시험이 진행된다는 점이 어려울뿐입니다

API 시험을 치고나서 느낌은?

시험코드는 반듯이 정독해보시고 시험 치세요 대분분의 문제가 해당코드에서 출제 됩니다 그리고 공부방법은 기출문제를 풀어보고 그문제가 어디에서 나오는지 알아야 한다는 것입니다 그것은 추가코드를 공부할때도 마찬가지 입니다 문제를 풀때 앞의 목차를 보면서 어디에서 나올것 같은지 한번씩 생각해 보시기를 추천 드립니다

아직 공유안한 자료들 많이 있습니다 혹시 필요하신분들 댓글 달아주세요 (510,570, 653, ASNT L3, CWI 등...기타 각종 코드 필요하신분들 )

국내 최저가 화상영어 추천(한달 6만원 20회 20분)

국내 최저가 화상영어 (한달 6만원 20회 20분)

국내 최저가 화상영어 추천(한달 5만원 20회 20분) 아직도 말 못하는 수업만 하고 계신가요? ‘영어는 공부’가 아니라 ‘언어’라는 점을 아셔야 합니다 때문에 당연히 원어민과 대화를 하면서

qi-inform.tistory.com

1) In a welding procedure transverse joint tensile test the following observations were made. The specimen CSA was recorded as 25mm x 12mm and the maximum load applied was recorded as 150kN. What is the UTS?

| a. | 50kN/mm2 |

| b. | 5500N/mm2 |

| c. ( answer ) | 500N/mm2 |

| d. | 50N/mm2 |

- Transverse tensile test:

- CSA: cross section area

- UTS: ultimate tensile strength ( N/mm2; p.s.i; Mpa )

- UTS = (150×1000)/(25×12) = 500N/mm2

- Pls take note for unit of value.

2) In welder qualification testing of 10mm plates, 2 root and 2 face bends were test … what course of action would you follow?

| a. | Accept them as 75% were acceptable, you are allowed one failure |

| b. | 2 more root bends should be prepared and tested |

| c. | 2 more root and 2 more face bends should be prepared and tested |

| d. | Retest the welder |

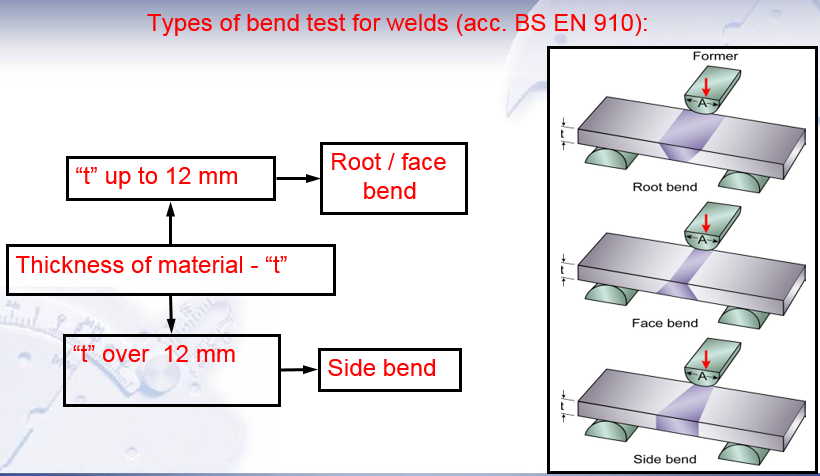

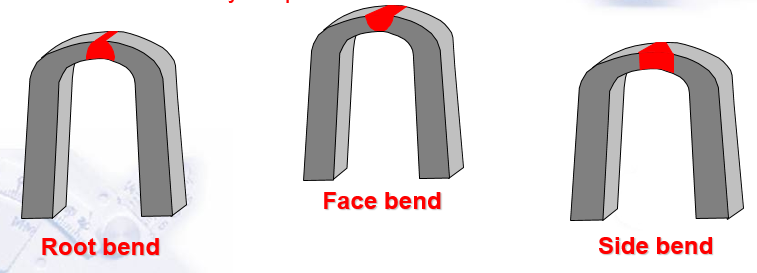

- Bend test: To determine the soundness of the weld zone. Bend testing can also be used to give an assessment of weld zone ductility. There are three ways to perform a bend test: Face bend, root bend & side bend (Generally for materials above 12mm thickness).

- But this question is for Welder.

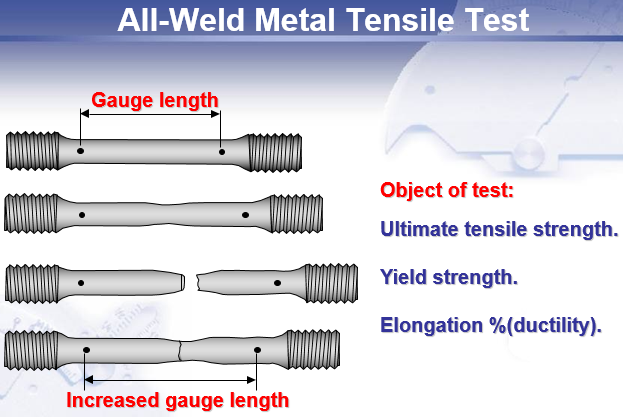

3) In an all weld tensile test, the original specimen gauge length was 50mm, and after the test the increased gauge length was 60mm, what is the elongation percentage?

| a. | %A is 50 |

| b. | %A is 20 |

| c. | %A is 29 |

| d. | %A is 36 |

E= (60-50)*100/50 = 20%. So, righ answer is “b”.

4) Some codes require the excess weld metal (weld cap) on cross weld joint tensile specimens to be flush, this is because:

| a. | Flushed caps will always break in the weld metal area |

| b. | This is to remove any porosity in the excess weld metal (weld cap) |

| c. | It is easier to calculate the cross sectional area of the joint when flushed |

| d.( answer ) | Flushed caps have fewer stress raisers and therefore give a more accurate result |

Note that the stress raiser at the toe of the weld cap will make incorrect stress result.

5) When transverse tensile testing a welded joint the excess weld metal is often removed. This action is done to:

| a. | Allow the test piece to fit accurately into the equipment |

| b. ( answer ) | Reduce stress concentrations to the weld toes |

| c. | Allow strain gauges to be placed over the weld face area |

| d. | Allow weld metal ductility to be measured |

see previous question!

6) In welder qualification testing of 20mm plates, why are side bends used instead of root and face bends:

| a. | They are easier to produce |

| b. | The testing equipment cannot handle thick root/face bends |

| c. | Root defects are not important for welder qualification |

| d. ( answer ) | They give more accurate indications |

Bend test: To determine the soundness of the weld zone. Bend testing can also be used to give an assessment of weld zone ductility.

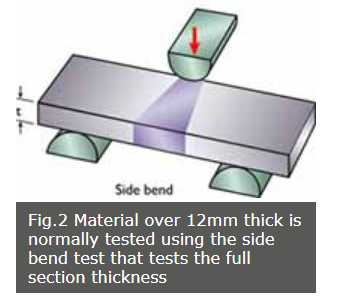

Side bend tests are normally carried out on welds over 12mm in thickness.

When make the “Side bend”, 3 area as: root, face & side will be tested. That tests test the full section thickness. So, it gives more accurate indications.

Specimens and testing for bend testing for butt joints shall be in accordance with EN 910.

For thicknesses < 12 mm two root and two face bend test specimens shall be tested. For thicknesses 12 mm four side bend specimens are recommended instead of root and face bend tests.

7) Mechanical tests are divided into two areas, identify these from the list below:

| a. | Destructive and non destructive tests |

| b. ( answer ) | Qualitative and quantitative |

| c. | Visual and mechanical |

| d. | Qualitative and visual |

Quantitative Tests: For measuring a ‘quantity’ ( a mechanical property )

Qualitative Tests: For assessing joint ‘quality’ (good fusion & free from defects)

The following mechanical tests have units and are termed quantitative tests to measure Mechanical Properties:

- Tensile tests (Transverse Welded Joint, All Weld Metal)

- Toughness testing (Charpy, Izod, CTOD)

- Hardness tests (Brinell, Rockwell, Vickers)

The following mechanical tests have no units and are termed qualitative tests for assessing joint quality:

- Macro testing

- Bend testing

- Fillet weld fracture testing

- Butt weld nick-break testing

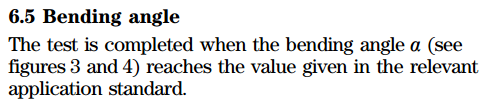

8) When examining a completed bend test, the angle of the bend was found to be 175o. The testing specification calls for the sample to have been formed through 180o.

| a. | The bends should be considered as falled |

| b. ( answer ) | They should be bent to 180o then re-examined |

| c. | They should be acceptable as the reduction in angle is due to material spring back |

| d. | They should be rejected as the angle is not close enough to be acceptable |

Follow BS EN – 910:

9) Charpy testing is carried out on a welding procedure test plate because?

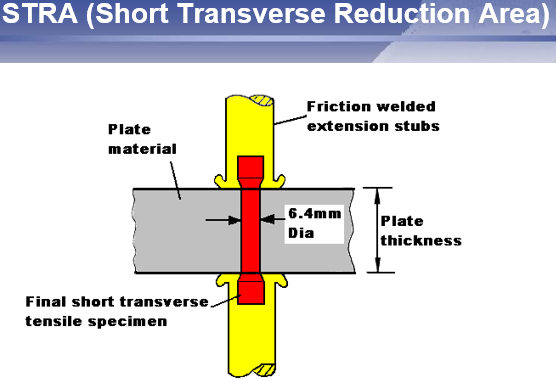

| a. | It gives an indication of the through thickness ductility (in the Z direction) |

| b. ( answer ) | The impact test results can be used to verify that the material has not been adversely affected by the heat of the welding |

| c. | It gives an indication of the materials elongation properties |

| d. | It gives a quick indication of the weld quality for welder qualification tests |

Some question we need use “exclusion method”.

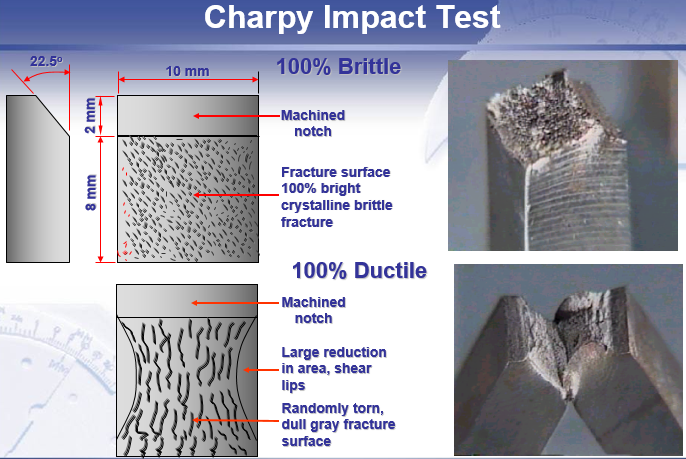

Charpy testing:

a) It gives an indication of the through thickness ductility (in the Z direction): this for STRA not Charpy impact test.

c) It gives an indication of the materials elongation properties:

d) It gives a quick indication of the weld quality for welder qualification tests: welder qualification test don’t require Chapry impact test.

b) The impact test results can be used to verify that the material has not been adversely affected by the heat of the welding: this is correct answer.

10) Charpy impact tests show a 50% rough torn surface and a 50% flat crystalline surface after the completed test, this would indicate which type of failure?

| a. | Fatigue to brittle |

| b. ( answer ) | Ductile to brittle |

| c. | Ductile with gross yielding |

| d. | Fatigue to ductile |

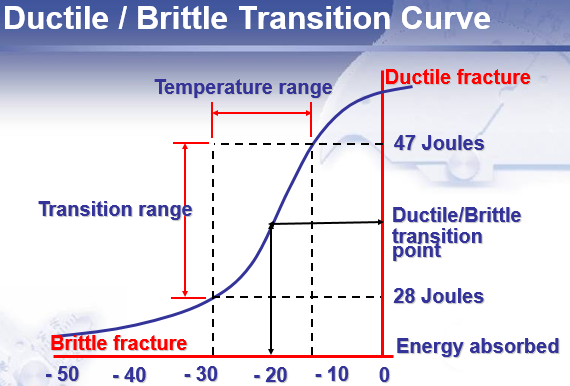

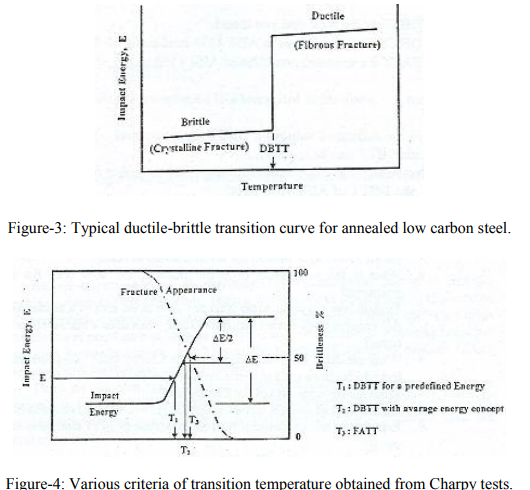

Charpy impact test: These tests show that metals can be classified as being either ‘brittle’ or ‘ductile’. A brittle metal will absorb a small amount of energy when impact tested, a tough ductile metal a large amount of energy.

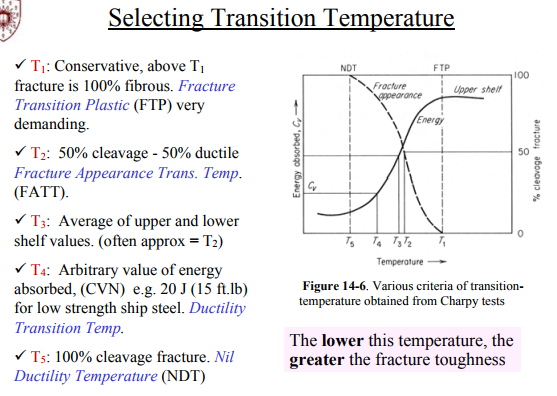

Some steels may show transition characteristics in their failure mode from ductile to brittle gradually as temperature is decreased, which is given in Figure-4 schematically. In this case different approaches may be used in determining transition temperature but the average energy concept is the most popular one. Determination of transition temperature can also be done by examining the fracture surfaces of specimens tested at different temperatures. For example the temperature, at which the fracture surface consists 50 percent cleavage (crystalline) and 50 percent ductile (fibrous) types of fracture, is called fracture appearance transition temperature (FATT). Another common criterion is to determine the transition temperature on the basis of an arbitrary energy absorbed.

'inspection > CSWIP' 카테고리의 다른 글

| CSWIP3.1 기출 Q&A 해설 6(번역 포함) (1) | 2023.02.15 |

|---|---|

| CSWIP3.1 기출 Q&A 해설 5 (0) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 4 (2) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 2 (0) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 1 (0) | 2023.02.14 |

댓글