해외 검사원 자격시험 자료 공유합니다

먼저 영어 공부를 선행하시고 시험 준비하기를 권장드립니다 본인은 일전에 드릴쉽승선해서 검사한 경험있는데 영어가들리지 않아 곤란한경험이 여러번있었습니다

일단 해외자격시험은 국내 자격보다 어렵지 않습니다 다만 영어로 시험이 진행된다는 점이 어려울뿐입니다

API 시험을 치고나서 느낌은?

시험코드는 반듯이 정독해보시고 시험 치세요 대분분의 문제가 해당코드에서 출제 됩니다 그리고 공부방법은 기출문제를 풀어보고 그문제가 어디에서 나오는지 알아야 한다는 것입니다 그것은 추가코드를 공부할때도 마찬가지 입니다 문제를 풀때 앞의 목차를 보면서 어디에서 나올것 같은지 한번씩 생각해 보시기를 추천 드립니다

아직 공유안한 자료들 많이 있습니다 혹시 필요하신분들 댓글 달아주세요 (510,570, 653, ASNT L3, CWI 등...기타 각종 코드 필요하신분들 )

국내 최저가 화상영어 추천(한달 6만원 20회 20분)

국내 최저가 화상영어 (한달 6만원 20회 20분)

국내 최저가 화상영어 추천(한달 5만원 20회 20분) 아직도 말 못하는 수업만 하고 계신가요? ‘영어는 공부’가 아니라 ‘언어’라는 점을 아셔야 합니다 때문에 당연히 원어민과 대화를 하면서

qi-inform.tistory.com

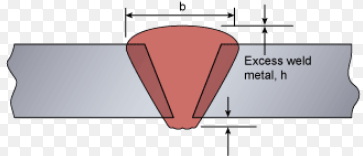

1) A code give the acceptance standard for excess weld metal “h” as h ≤ 1mm + 0.1b, max. 5mm, where “b” is the width of the weld cap. For which of the following situations is the excess weld metal acceptable?

| a. | b = 15 h = 3.0 |

| b. ( answer ) | b = 22 h = 3.0 |

| c. | b = 28 h = 4.0 |

| d. | b = 40 h = 5.4 |

from b = 22 –> h<=3.2 < 3.0. So, “b” is righ answer.

2) A long centreline crack has been detected in a submerged arc weld bead this may be due to:

| a. | Use of a high manganese filler wire |

| b. | Use of a damp flux |

| c. ( answer ) | Weld bead is deep and narrow |

| d. | Use of too high voltage |

The long centreline crack is Solidification Cracking (hot crack) can occur when:

-Weld metal has a high carbon or impurity (sulphur) content

–The depth-to-width ratio of the solidifying weld bead is large (deep & narrow)

-Disruption of the heat flow condition occurs, stop/start condition

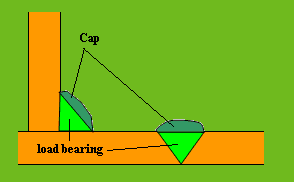

3) Which of the following defects will have the more severe effect on the load-bearing capacity of a weld?

| a. | Undercut |

| b. ( answer ) |

Incompletely filled groove |

| c. | Irregular width |

| d. | Excess penetration |

Pls understand that: The Cap on the weld is weld filler that does not contribute to the load bearing structure of the weld.

4) While inspecting a weld on a 100mm thick high carbon steel plate with a … the weld is visually acceptable, however the parent material has severse … the weld approximately 3mm deep, what course of action would you …

| a. | None I am only inspecting the weld |

| b. | Recommend that the area be dressed smooth |

| c. ( answer ) | Recommend that the area be dressed smooth followed by MPI |

| d. | High carbon steel is not susceptible to cracking so I would weld over … |

- High carbon steel is susceptible to cracking. So, weld over it to be careful.

- We have to inspect at weldment & parent material ( base metal ) also.

- The defect to be dressed smooth with MPI to make sure that all defect are removed completely.

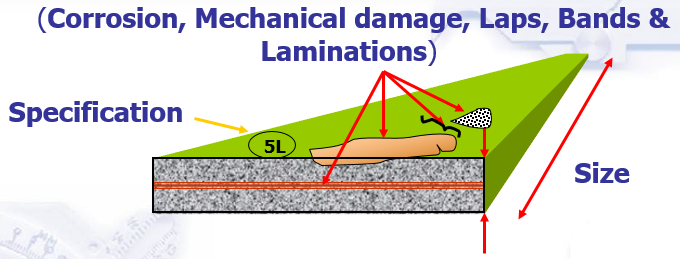

Pls take note: All materials arriving on site should be inspected for:

- Size / dimensions

- Condition

- Type / specification

5) Which of these statements are true concerning Lamellar tearing?

| a. | As hydrogen levels increase Lamellar tearing is more likely |

| b. | As material thickness increases ductility decreases making Lamellar tearing more likely |

| c. ( answer ) | Lamellar tearing occurs in the HAZ |

| d. | Lamellar tearing affects all joint types |

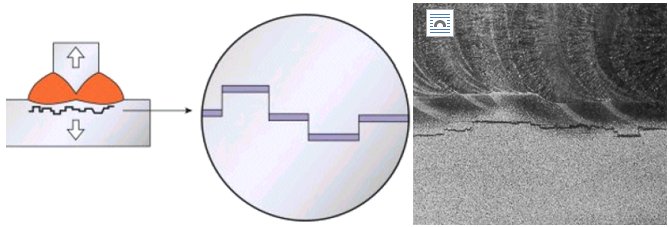

What is Lamellar tearing?

LAMELLAR TEARING occurs only in rolled steel products. Cracking occurs in joints where:

-A thermal contraction strain occurs in the thru. thickness direction of steel plate

-Non-metallic inclusions are present as very thin platelets with their principal planes parallel to plate surface

Two main options are available to control the problem in welded joint liable to lamellar tearing:

-Use clean steel with guarantee through-thickness properties (Z grade)

-A combination of joint design, restraint control and welding sequence to minimize the risk of cracking

Location: Parent metal

Steel Type: Any steel type possible

Susceptible Microstructure: Poor through thickness ductility

- Lamellar tearing has a step like appearance due to the solid inclusions in the parent material (e.g. sulphides and silicates) linking up under the influence of welding stresses

- Low ductile materials in the short transverse direction containing high levels of impurities are very susceptible to lamellar tearing

- It forms when the welding stresses act in the short transverse direction of the material (through thickness direction)

6) Which of the following types of imperfection is generally considered to be the most serious?

| a. ( answer ) | Surface breaking planar |

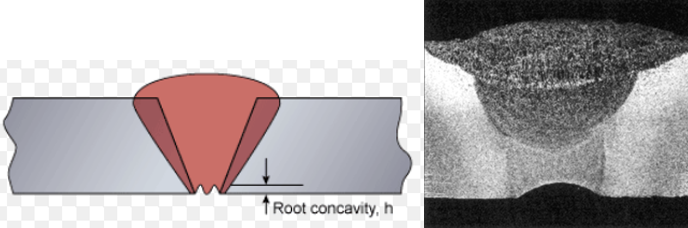

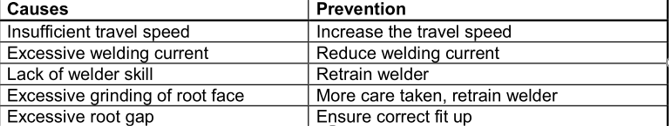

| b. | Root concavity |

| c. | Buried planar |

| d. | Surface breaking non-planar |

- Root concavity:

- Buried planar: the deject stay in side of weld

7) Burn through may occur because the:

| a. | Current is too high |

| b. | Root gap is too small |

| c. | Travel speed is too fast |

| d. | Current is too low |

Burn Through: a collapse of the weld pool resulting in a hole in the weld

8) On inspecting a completed 150mm OD pipe weld some small smooth, shallow areas of undercut have been found < 0.25mm deep. The welder says he can quickly put this right by depositing a thin narrow bead along the undercut. In this situation would you?

| a. | Agree to go ahead with no preheat as the weld is so small |

| b. | Only allow the welder to cosmetically blend out the undercut providing the wall thickness remains within the specification tolerances |

| c. | Agree to go ahead with a preheat 50oC above original |

| d. | Cut out the joint and re-weld |

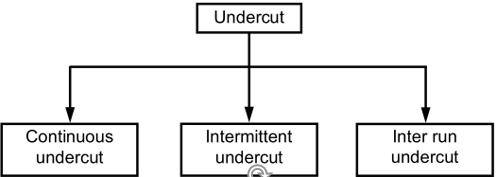

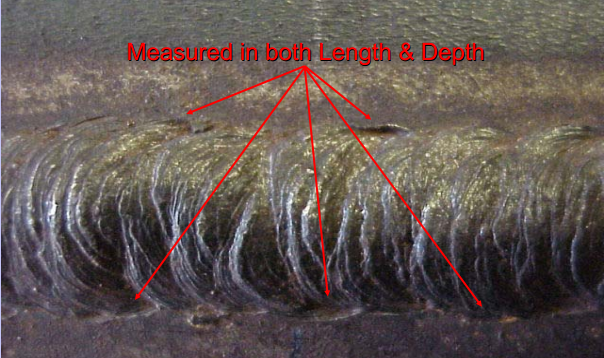

Have 3 type of Undercut defect, they have to be measured in both length & depth. After that compare with specification / tolerance for assessment.

9) On inspecting a completed weld which has Charpy impact requirements some small areas of undercut have been found. The welder says he can quickly put this right by depositing a thin narrow bead along the undercut. In this situation would you?

| a. | Agree to go ahead with no preheat as the weld is so small |

| b. | Agree to go ahead with the same preheat as the original weld |

| c. | Agree to go ahead with a preheat 50oC above original |

| d. ( answer ) | Only allow the welder to cosmetically blend out the undercut |

See previous question!

10) Why would visual inspection of the excess weld metal at the bottom of a cross country pipeline be important?

| a. ( answer ) | It is the most difficult area to weld |

| b. | It is the dirtiest part of the pipe as it is near the ground |

| c. | Welders always forget to weld the bottom |

| d. | It is the most difficult area to radiograph |

What is Cross country pipeline? See below pciture:

At bottom of pipeline is hard to weld.

'inspection > CSWIP' 카테고리의 다른 글

| CSWIP3.1 기출 Q&A 해설 6(번역 포함) (1) | 2023.02.15 |

|---|---|

| CSWIP3.1 기출 Q&A 해설 5 (0) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 4 (2) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 3 (0) | 2023.02.14 |

| CSWIP3.1 기출 Q&A 해설 2 (0) | 2023.02.14 |

댓글