국내 최저가 화상영어 추천(한달 5만원 20회 20분)

해외 검사원 자격시험 자료 공유합니다

먼저 영어 공부를 선행하시고 시험 준비하기를 권장드립니다 본인은 일전에 드릴쉽승선해서 검사한 경험있는데 영어가들리지 않아 곤란한경험이 여러번있었습니다

일단 해외자격시험은 국내 자격보다 어렵지 않습니다 다만 영어로 시험이 진행된다는 점이 어려울뿐입니다

API 시험을 치고나서 느낌은?

시험코드는 반듯이 정독해보시고 시험 치세요 대분분의 문제가 해당코드에서 출제 됩니다 그리고 공부방법은 기출문제를 풀어보고 그문제가 어디에서 나오는지 알아야 한다는 것입니다 그것은 추가코드를 공부할때도 마찬가지 입니다 문제를 풀때 앞의 목차를 보면서 어디에서 나올것 같은지 한번씩 생각해 보시기를 추천 드립니다

아직 공유안한 자료들 많이 있습니다 혹시 필요하신분들 댓글 달아주세요 (510,570, 653, ASNT L3, CWI 등...기타 각종 코드 필요하신분들 )

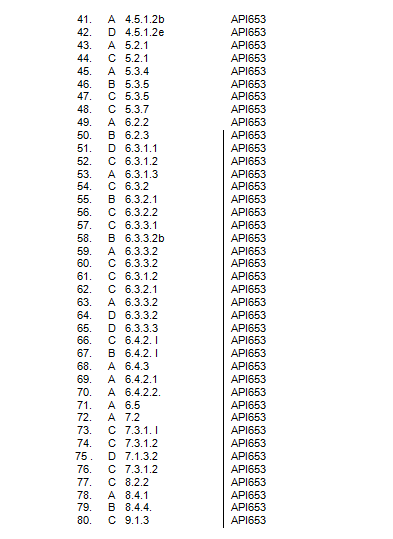

41. Calcining ___________.

a. Can occur when concrete has been exposed to sufficient high temperature.

b. Can occur when tank has been exposed to sufficient high temperature.

c. Can occur when tank roof exposed to with calcium product in tank.

d. None of the above.

42. Temperature cracks do not seriously affect the strength of the________ structure.

a. Roof.

b. Tank supports.

c. Shell.

d. Concrete foundation.

e. None of the above.

43. The following all are tank failure due to brittle fracture but not this one_____.

a. Tank continuously served in low temperature service.

b. After erection during hydrostatic testing.

c. First filling in cold weather.

d. After a change to lower temperature service.

e. None of the above.

44. A tank has demonstrated the ability to with stand the combined effects of maximum liquid level and lower operating temperature without failing. For the above tank, whether the risk of failure due to brittle fracture with continued service in minimal?

a. No, brittle fracture will depend on low temperature of product.

b. No, brittle fracture is not dangerous in tank by experience.

c. Yes it is minimal.

d. None of the above.

45. If a tank shell thickness is no greater than _______ the risk of failure due to brittle facture is minimal.

a. ½ in.

b. ¼ in.

c. ¾ in.

d. 1/8 in.

46. By the experience brittle fracture will not occurred at shell metal temperature above ___________.

a. Ambient.

b. 60°F.

c. 100°F

d. 0°F.

47. To avoid brittle fracture some tanks have heaters this heaters will increase the metal temperature by heating the _________.

a. Shell plate.

b. Bottom plate.

c. Tank contents.

d. Fire water line.

48. Tanks fabricated from steels of unknown toughness thicker than _______ operating at a shell metal temperature below __________ can be used if the tank meets the requirements of brittle fracture consideration.

a. 1 in ; Ambient

b. 1 in ; 60°F.

c. ½ in ; 60°F.

d. ½ in ; Ambient

49. The interval between inspections of tank should be determined by its service _______ unless special reasons indicate that an earlier inspection must be made.

a. History

b. Life

c. Severity

d. All of the above

50. In some cases _______ also control the frequency and interval of the inspection.

a. National board regulations.

b. Jurisdictional regulations.

c. Owner/operator regulations.

d. Authorized inspector.

51. Routine In-service inspections can be done by

a. Owner/operator personnel.

b. Authorized inspector.

c. Who has knowledge about the tank and its operation.

d. All of the above.

52. The interval of routine in-service inspections shall be consistent with conditions at the particular site, but shall not exceed ___________.

a. 5 years.

b. Six months.

c. One month.

d. One year.

53. Routine in-service inspection shall include the following and not this one?

a. Thickness check.

b. Visual inspection.

c. Evidence of leak.

d. Shell distortions.

e. Corrosion.

54. External inspection for all tanks shall be given a visual external inspection by authorized inspector. For this inspection maximum interval will be _____.

a. 5 years.

b. 5 years or RCA/2N years, which ever is less.

c. 5 years or RCA/4N years, which ever is less.

d. 5 years if corrosion allowance known, 15 years if corrosion allowance not known.

55. External inspection for all tanks shall be done by Al. And during this inspection that tank ________________________.

a. Shall be in operation during this inspection.

b. May be in operation during this inspection.

c. Should be in operation during this inspection.

d. None of the above.

56. You are the inspector for tank to do external inspection. And tank was insulated by 150mm outside insulation and covered by aluminum sheets. What will be your action?

a. Remove small area for inspection and cover it properly after inspection.

b. Removal of insulation is not at all required for external inspection.

c. Insulation removal only for necessary area to check the external wall.

d. It is always authorized inspector’s option to open insulation.

57. The extent of ultrasonic thickness measurement inspection shall be determined by …………………

a. Authorized inspector.

b. UT operator.

c. Owner/operator.

d. Tank design engineer.

58. When the corrosion rate is known what will be the maximum interval of ultrasonic thickness inspection?

a. 5 years.

b. 15 years.

c. RCA/4N.

d. Both ‘a’ and ‘c’ which ever is smaller.

e. None of the above.

59. Whether external inspection can be substituted for a internal inspection?. If yes what is the maximum interval.

a. No.

b. Yes.

c. Yes, if external inspection interval is equal to or less than interval required for internal inspection.

d. None of the above.

60. You have calculated external inspection interval as 2 years, then what will be the ultrasonic thickness inspection interval?

a. 1 year.

b. 2 years.

c. 4 years.

d. None of the above.

e. Not enough data to calculate ultrasonic thickness inspection interval.

For question number 61 to 65 the following data are to be used.

Tank No. : ABC 650

Thickness of tank shell plate when installed : 0.505 inch.

Thickness of tank shell plate required by design : 0.255 inch.

Ultrasonic Thickness at present is : 0.375 inch.

Installed on : June 1993

61. What is the maximum routine in-service inspection interval for the tank ABC 650?

a. 3 years.

b. 11/2 year.

c. 1 month.

d. 5 years.

62. External inspection interval for tank ABC 650 is?

a. 6 years.

b. 1½ year.

c. 3 years.

d. 5 years.

e. 15 years.

63. Ultrasonic inspection interval for tank ABC 650 is?

a. 6 years.

b. 1½ year.

c. 3 years.

d. 5 years.

e. 15 years.

64. Ultrasonic inspection interval for tank ABC 650 if corrosion allowance not known will be?

a. 6 years.

b. 1½ year.

c. 3 years.

d. 5 years.

e. 15 years.

65. For the tank ABC 650 the next internal inspection data will be around June 2008, and the last external inspection were did in June 2006. What will be the next external inspection data?

a. June 2006

b. Jan 2008

c. June 2012

d. No need of next one external inspection.

e. None of the above.

66. Internal inspection carryout when tank _________.

a. In shutdown only, because inspector has to do visual inside.

b. In-service only.

c. In-service also can do, if some alternative of inspection to get the requirements of internal inspection programme.

d. None of the above.

67. The maximum intervals of internal inspection shall not exceed in any case more than _______________.

a. 10 years.

b. 20 years.

c. 5 years.

d. Depends on corrosion rate.

68. RBI analysis should be reviewed at least once in __________.

a. 10 years.

b. 20 years.

c. 5 years.

d. Depends on corrosion rate.

69. Internal inspection interval normally controlled by ……………..

a. Bottom corrosion.

b. Bottom and shell corrosion

c. Bottom, shell and roof corrosion.

d. By RBI

e. None of the above.

70. When corrosion rates are not known and similar service experience is not available to estimate bottom plate minimum thickness at the next inspection, the inspection interval shall not exceed____________.

a. 10 years.

b. 20 years.

c. 5 years.

d. Owner/operator should decide.

e. Authorized inspector should decide.

71. If external inspection can access to all the area of tank, then the internal inspection can be eliminated.

a. Yes.

b. No, internal inspection never eliminated by external inspection.

c. Depends on owner-operator requirements.

d. None of the above.

72. All new material used for repair, alteration, or reconstruction shall confirm to ___

a. Current applicable tank standards.

b. Applicable tank standard.

c. Construction code.

d. API 653

e. API 650

73. All _______________ materials shall be identified.

a. Shell, bottom and roof plates.

b. Shell and bottom plates.

c. Shell and bottom plates welded to the shell.

d. All the above.

74. Material not identified shall be tested accordance with _______________

a. ASTM A20 and A6

b. API 650

c. ASTM A6 and A370

d. API 653 App. D

75. When material not identified shall be tested, for this test specimen selection by ____________.

a. One per heat.

b. One per lot

c. One per tank

d. Each plate.

76. How many tension specimen required when direction of rolling not known during mechanical test to identify materials which is used for reconstruction?

a. 4

b. 1

c. 2

d. 2 for less than or equal to 1” and 4 for above 1”.

77. For tank all new shell joints shall be _____ with complete penetration and complete fusion.

a. Lap weld.

b. Full weld.

c. Butt weld.

d. Groove weld.

78. When tank is planned to reconstruction, thickness to be used each shell course when checking tank design shall be based on measurement taken_________.

a. With in 180 days prior to relocation.

b. Current thickness prior to relocation.

c. After relocation new thickness readings shall be taken.

d. Last ultrasonic thickness measurement can use.

e. None of the above.

79. For reconstruction tank, when calculating the maximum liquid level, if the actual thickness is greater than that necessary to allow the liquid level required, the extra thickness can be considered _______________.

a. For calculating maximum liquid level.

b. As corrosion allowance.

c. Excess thickness.

d. As a wrong selection of thickness.

80. All repair work must be authorized by ________ before commencement of the work by a repair organization.

a. Authorized inspector.

b. Engineer experienced in storage tank design.

c. ‘a’ or ‘b’

d. The owner/operator.

'inspection > API653 시험자료' 카테고리의 다른 글

| API 653 계산문제 풀이 1 (0) | 2021.10.21 |

|---|---|

| API 653 OPEN BOOK 1-2 (1) | 2021.10.19 |

| API 653 OPEN BOOK 1-1 (0) | 2021.10.19 |

| API 653 CLOSED BOOK 1-3 (1) | 2021.10.19 |

| API 653 CLOSED BOOK 1-1 (0) | 2021.10.19 |

댓글