해외 검사원 자격시험 자료 공유합니다

먼저 영어 공부를 선행하시고 시험 준비하기를 권장드립니다 본인은 일전에 드릴쉽승선해서 검사한 경험있는데 영어가들리지 않아 곤란한경험이 여러번있었습니다

일단 해외자격시험은 국내 자격보다 어렵지 않습니다 다만 영어로 시험이 진행된다는 점이 어려울뿐입니다

API 시험을 치고나서 느낌은?

시험코드는 반듯이 정독해보시고 시험 치세요 대분분의 문제가 해당코드에서 출제 됩니다 그리고 공부방법은 기출문제를 풀어보고 그문제가 어디에서 나오는지 알아야 한다는 것입니다 그것은 추가코드를 공부할때도 마찬가지 입니다 문제를 풀때 앞의 목차를 보면서 어디에서 나올것 같은지 한번씩 생각해 보시기를 추천 드립니다

아직 공유안한 자료들 많이 있습니다 혹시 필요하신분들 댓글 달아주세요 (510,570, 653, ASNT L3, CWI 등...기타 각종 코드 필요하신분들 )

국내 최저가 화상영어 추천(한달 6만원 20회 20분)

국내 최저가 화상영어 (한달 6만원 20회 20분)

국내 최저가 화상영어 추천(한달 5만원 20회 20분) 아직도 말 못하는 수업만 하고 계신가요? ‘영어는 공부’가 아니라 ‘언어’라는 점을 아셔야 합니다 때문에 당연히 원어민과 대화를 하면서

qi-inform.tistory.com

1) Which of the following processes is most prone to solidification cracks?

다음 공정 중 응고 균열이 가장 많이 발생하는 공정은?

| a. | MMA with basic coated electrodes |

| b. | MMA with rutile coated electrodes |

| c. | TIG |

| d. ( answer ) | SAW |

Solidification also referred as Hot Cracking.

Solidification Cracking (hot crack) can occur when:

-Weld metal has a high carbon or impurity (sulphur) content

-The depth-to-width ratio of the solidifying weld bead is large (deep & narrow)

-Disruption of the heat flow condition occurs, stop/start condition

2) Which of the following could be used to minimise the occurrence of solidification cracks in steels welds?

다음 중 강재 용접부의 응고 균열 발생을 최소화하기 위해 사용할 수 있는 것은?

| a. | Increase sulphur levels to a minimum of 0.5% |

| b. ( answer ) | Reduce the dilution into the base metal |

| c. | Increase carbon content in the weld metal |

| d. | Reduce the manganese content in the weld metal |

3) Hydrogen cracking is considered a cold crack as it will not form till the weldment cools to below:

수소 균열은 용접물이 아래로 냉각될 때까지 형성되지 않으므로 냉간 균열로 간주됩니다.

| a. | 500oC |

| b. ( answer ) | 300oC |

| c. | 300oF |

| d. | 730oC |

300oF = 149oC

400oF = 205oC

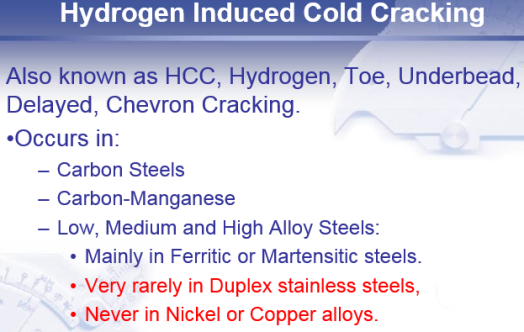

HYDROGEN INDUCED CRACKS: As know cold cracking, delayed cracking or underbead/toe cracking.

4) In a heavy plate fabrication where S is residual @0.3%, which may cause problems in the welded joint, additions of Mn may be added to prevent:

S가 잔류 @0.3%인 후판 제작에서 용접 조인트에 문제를 일으킬 수 있으므로 다음을 방지하기 위해 Mn을 추가할 수 있습니다 .

| a. | Laminations in the plate through thickness |

| b. | Stress corrosion cracks |

| c. | Manganese sulphides (MnS) |

| d. ( answer ) | Solidification cracking |

Solidification Cracking (hot crack) can occur when: Weld metal has a high carbon or impurity (sulphur) content.

Precautions for controlling solidification cracking:

Add Manganese to the electrode to form spherical Mn/S which form between the grain and maintain grain cohesion.

As carbon increases the Mn/S ratio required increases exponentially and is a major factor. Carbon content % should be a minimised by careful control in electrode and dilution.

5) Inspection for hydrogen cracking is often specified to be done between 48 to 72 hrs after completion of the weld, this is because?

수소균열 검사는 용접종료 후 48~72시간 사이에 실시하는 경우가 많은데 그 이유는?

| a. | The stress level will have reduced by then |

| b. ( answer ) | It is the maximum time it taken for all the H2 to diffuse out of the weld |

| c. | Usually after 48 hrs such cracking is unlikely to occur |

| d. | It is to ensure the weld has property cooled down to ambient temperature |

Typically, hydrogen-induced cracking occurs at temperatures below 600 degrees Fahrenheit (more commonly around or below 300 degrees Fahrenheit) and within 48 hours of completing the weld. In some cases, it can occur as much a week after welding.

In applications with greater contributing factors — highly restrained joints; high levels of hydrogen; or rapid cooling after weld completion — hydrogen-induced cracking can occur much sooner, even immediately.

6) Preheats are used on steel joints of high hardenability mainly to:

예열은 주로 다음과 같이 경화성이 높은 강철 조인트에 사용됩니다.

| a. ( answer ) | Slow the cooling rate of the steel |

| b. | Remove surface moisture from the joint |

| c. | Reduce the formation of surface oxides |

| d. | Increase the diffusion rate of hydrogen into the HAZ |

There are four primary reasons to utilize preheat:

(1) it lowers the cooling rate in the weld metal and base metal, producing a more ductile metallurgical structure with greater resistant to cracking

(2) the slower cooling rate provides an opportunity for any hydrogen that may be present to diffuse out harmlessly without causing cracking

(3) it reduces the shrinkage stresses in the weld and adjacent base metal, which is especially important in highly restrained joints and

(4) it raises some steels above the temperature at which brittle fracture would occur in fabrication. Additionally, preheat can be used to help ensure specific mechanical properties, such as notch toughness.

7) Sensitisation is a term applied to the formation of which intermetallic compound at the grain boundaries in the HAZ of austenitic stainless steels?

예민화는 오스테나이트계 스테인리스 강의 HAZ의 입계에서 어떤 금속간 화합물의 형성에 적용되는 용어입니까?

| a. ( answer ) | Chromium carbide |

| b. | Titanium carbide |

| c. | Niobium carbide |

| d. | Molybdenum carbide |

Crack type: Inter-granular corrosion

Location: Weld HAZ. (longitudinal)

Steel types: Stainless steels

Microstructure: Sensitised grain boundaries*

Occurs when:

An area in the HAZ has been sensitised by the formation of chromium carbides.This area is in the form of a line running parallel to and on both sides of the weld. This depletion of chromium will leave the effected grains low in chromium oxide which is what produces the corrosion resisting effect of stainless steels. If left untreated corrosion and failure will be rapid*

8) When comparing the properties of plain carbon steels and austenitic stainless steels … which of the following statements is true?

일반 탄소강과 오스테나이트계 스테인리스강의 특성을 비교할 때 … 다음 설명 중 참인 것은 무엇입니까?

| a. ( answer ) | Carbon steels have better thermal conductivity |

| b. | Stainless steels have low expansion and contraction |

| c. | Carbon steels have higher expansion rates in the Z direction |

| d. | Stainless steels have lower chromium |

Austenitic stainless steels have high ductility, low yield stress and relatively high ultimate tensile strength, when compare to a typical carbon steel.

Plain Carbon Steels:

- Low Carbon Steel 0.01 – 0.3% Carbon

- Medium Carbon Steel 0.3 – 0.6% Carbon

- High Carbon Steel 0.6 – 1.4% Carbon

Plain carbon steels contain only Iron & Carbon as main alloying elements, but traces of Mn, Si, Al, S & P may also be present.

Austenitic Grades:

- Non-magnetic

- Low thermal conductivity (‘hold’ the heat during welding)

- High coefficient of expansion – more distortion during welding

9) Weld decay occurs in which of the following steel types:

용접 부식은 다음 강종에서 발생합니다.

| a. | Carbon Manganese |

| b. | Low alloy |

| c. | Any stainless steels |

| d. ( answer ) | Austenitic stainless steels |

Inter-Granular Corrosion Also known as Weld Decay

- Location: Weld HAZ. (longitudinal

- Steel Type: Austenitic stainless steels

- Susceptible Microstructure: Sensitised HAZ grain boundaries

10) Which of the following materials is most susceptible to hydrogen cracking?

다음 중 수소 분해에 가장 취약한 물질은?

| a. | Low carbon steel |

| b. | Austenitic stainless steel |

| c. (answer) | High strength low alloy steel |

| d. | Aluminium |

'inspection > CSWIP' 카테고리의 다른 글

| CSWIP3.1 기출 Q&A 해설 18(번역 포함) (0) | 2023.03.14 |

|---|---|

| CSWIP3.1 기출 Q&A 해설 17(번역 포함) (0) | 2023.03.14 |

| CSWIP3.1 기출 Q&A 해설 15(번역 포함) (0) | 2023.03.13 |

| CSWIP3.1 기출 Q&A 해설 14(번역 포함) (7) | 2023.03.13 |

| CSWIP3.1 기출 Q&A 해설 13(번역 포함) (0) | 2023.03.08 |

댓글